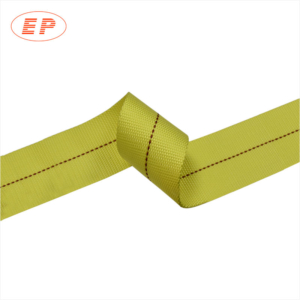

According to the definition of WIKI, “web straps is a strong fabric, woven into different width of the flat bar or tube, fiber is usually used instead of rope. It is a climb, relaxation, furniture manufacturing, car safety, car racing, Traction, parachuting, uniforms, load protection and many other areas of multi-functional components.

How to choose the right web straps?

It really depends on your needs. First determine the pressure on the mesh below the pounds, and look at the above to see which ribbon is right for your range. And then decide whether your webbing will be used indoors or outdoors. Nylon is a very rugged ribbon, with many bright colors, but can be faded in the sun after repeated exposure, and can be stretched in the case of humidity of about 2%, re-use the length of the ribbon. Polypropylene is a lighter ribbon, but with U.V. protection, waterproof, overall is a great outdoor webbing. However, if repeated use of the skin, it will usually have a more standard color, and has a rough feeling. Polyester is a good outdoor or indoor mesh belt, durable wear.

|

|

Standard Industry Application of Web Straps

Organization throughout the industry. Standard web straps applications and related industries include:

- Safety belts and harnesses; automotive industry

- Hiking, backpacking and equipment; sports good retail clothing

- Seat belts and tapes; hospitals and medical industries

- Interior decoration (seat base); furniture manufacturing

- Uniforms (harnesses) and various professional accessories such as the police and the army

Conclusion

Polyester web straps is more expensive than nylon and this is why most tie-down companies have switched to lower quality nylon for their webbing. China-webbing use 3,800 pound polyester webbing instead of lower cost nylon so our China-webbing, and not our webbing, does all the stretching. It’s the reason we don’t have customers calling us to say our hooks are coming off of their load or that their straps are coming loose when traveling down the road.

More Related Post: