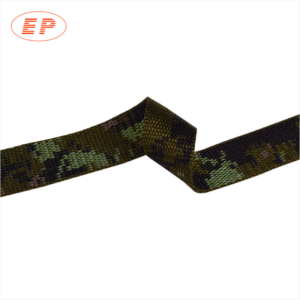

Nylon webbing uses the international parts of the dyeing technology, to create a high-end quality of a material, its flexibility beyond all expectations, and then it is a multi-color, multi-pattern products.

Nylon webbing lines are flat, herringbone, thread, forging and round dot pattern, etc., A variety of options for the user, and flexibility and tensile strength unchanged, more and more enterprises to use high-end webbing, Enhance the purpose of safe production, effectively avoid all kinds of accidents occurred.

You may also like our nylon webbing

Nylon composite materials

Flame retardant PA

As a result of PA in the addition of flame retardants, most of the flame retardant at high temperatures easily decomposed, the release of acidic substances, the metal has a corrosive effect, therefore, plastic components (screw, plastic head, Washers, flanges, etc.) to be hard chrome plating. The process, try to control the barrel temperature can not be too high, the injection speed can not be too fast, in order to avoid the material temperature is too high and decomposition caused by product discoloration and mechanical properties.

Transparent PA

Has good tensile strength, impact strength, rigidity, wear resistance, chemical resistance, surface hardness and other properties, high transmittance, and optical glass similar to the processing temperature of 300 – 315 ℃, molding processing, the need to Strict control of the barrel temperature, the melt temperature is too high due to degradation caused by product discoloration, the temperature is too low due to poor plastic products affect the transparency. Mold temperature as low as possible, the mold temperature will be due to crystallization of the transparency of the products reduced.

Weathering PA

In the PA by adding carbon black and other absorption of ultraviolet additives, this PA self-lubricating and metal wear greatly enhanced, forming the processing will affect the cutting and wear parts. Therefore, the need to use a strong feeding capacity and high wear resistance of the screw, barrel, a plastic head, a plastic ring, a rubber gasket combination. The repeating structure of the polyamide molecule chain is a polymer of the amide group alone.

To sum up, the benefits of nylon webbing mainly in the following aspects of modification.

- To improve the water absorption of nylon, to improve the dimensional stability of products.

- To improve the flame resistance of nylon to meet the electronics, electrical, communications and other industries.

- To improve the mechanical strength of nylon in order to achieve the strength of metal materials to replace the metal

- To improve the anti-low temperature performance of nylon and enhance its ability to resist environmental strain.

- To improve the wear resistance of nylon to meet the requirements of high wear and tear occasions.

- To improve the antistatic properties of nylon to meet the requirements of mining and its mechanical applications.

- To improve the heat resistance of nylon to adapt to the field of high-temperature conditions such as automotive engines.

- To reduce the cost of nylon, improve product competitiveness.

In short, through the above improvements, the realization of nylon composite materials, high performance and functional, and thus promote the relevant industry products to high-performance, high-quality direction.