There are many different materials, types and widths of webbing used in the Outdoor industries. Webbing is a strong fabric woven as a flat strip or tube of varying widths and fibers often used in place of rope.

Modern webbing is often made from exceptionally high-strength material, such as Nylon, Polyester, Polypropylene, and Kevlar. Some webbing characteristics that lend themselves well to outdoor gear is that it is easily sewn, it is strong, and it works well with hardware. From tree straps to backpack straps to your belt there is rarely any person on a hiking trip without some form of this under appreciated material.

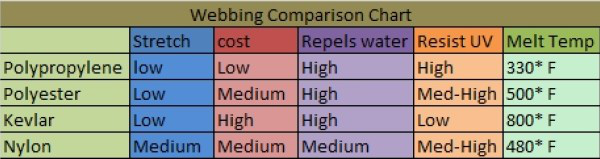

Materials- One of the biggest variations is often the hardest to see. The proper material for webbing is determined by the loads, stretch and other properties needed. Here is an outline of the most common ones used in the outdoor industry.

Nylon Performance Characteristics

- This type of webbing is unaffected by grease and oil

- It offers good chemical resistance

- Nylon webbing shouldn’t be used in acids or bleaching agents

- It may not be suitable to use in temperatures above 194°F, but is durable in extreme circumstances

- Elongation of approximately 10%

- Offers the ability to retract a good percentage of its stretch

- Helps avoid shock loading

Polyester Performance Characteristics

- This type of webbing is unaffected by grease and oil

- It offers good chemical and acid resistance

- This webbing shouldn’t be used in concentrated sulfuric acid

- It may not be suitable to use in temperatures above 194°F, but is durable in extreme circumstances

- Elongation of approximately 3%

- Makes load control easier by reducing bounce

The chart following is the comparison list among different materials: