What length of elastic webbing do I want to buy?

We do not have any minimum ribbon, all sold by foot, so you have to order one foot. However, depending on the quantity you have purchased, we will offer discounts for all of our web belts based on the full number. The size of a webbing is Flat Nylon 150 feet, 300 feet of polypropylene, 300 feet of polyester, 300 feet of tubular nylon. Please note that more than 30 feet of the order may have more than one, but you can ask your ribbon to reach a full block full limit, but please note that if we leave the stock full volume (rarely occurs).

|

|

What is a belt?

Belt is a combination of webbing and hardware, usually stitched together. The straps are used as fasteners to attach or bind items, animals and / or characters, or to securely bind equipment and vehicles. Depending on your needs and / or limitations, the belt can have many different combinations.

How do i determine the strength of my strap?

The overall strength of the strap is limited by its weakest point. This can be a ribbon, or a buckle. You need to understand that there are “breakthrough” advantages, there are “workloads”. The breaking strength is where the webbing or buckle will actually fail under static loads (eg, dead lifts). On the other hand, the workload is the maximum load used to take into account other factors (such as impact, drop, or tingling). Most manufacturers recommend that 33% of the breaking strength be used as the actual workload. If your button has a rating of 1000 lbs and your webbing is rated at 600 pounds, you must calculate your workload as 33% of the ribbon, or about 200 pounds.

Other Considerations: Replacement and Maintenance

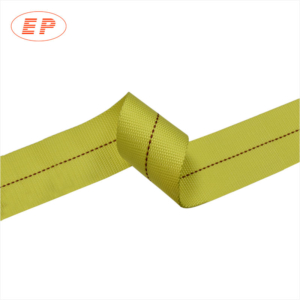

Professionals recommend checking materials annually, especially when using components as a security-constrained application. For example, belts and harnesses installed in the racing industry will begin to lose elasticity and tear after continuous use and exposure to certain elements such as oil and heat. Accordingly, if the application is regularly used, such as seat belts and chair seats, it is recommended to replace 2 to 5 years or faster. Synthetic Polyester Heavy Duty Elastic Webbing Belt

Maintenance is another important security consideration. Often, most elastic webbing should be kept clean and dry, although some materials such as polypropylene are waterproof. It is advisable to use a mild detergent to clean the elastic webbing, but it is also important to remember that the above materials are made in color and that they are faded or lost when exposed to certain conditions or detergent treatment. Therefore, consult the manufacturer for the best maintenance method.

More related post:

Elastic Webbing FAQs that Should be Considered

Where to Buy Webbing – Make Your Mark with Custom Sublimated Creations