How to print on ribbon is a question that might trouble many business owners. As the age changed, printed webbing has

become more and more necessary. Thus the technology also become more differentiation.

Screen Printing

Historically, this is one of the oldest systems, although it has lost its favor, but screen printing still offers the best solution. In

this method, the screen is coated with a photographic emulsion and allowed to dry. Once dried, place the screen on the vacuum

lamp table, where it is exposed to the halide lamp with high wattage. After this step, the screen was washed with a pressure

cleaner of 1300 psi to display the image. It can then be mounted on a screen printer. In screen printing, each color in the image

being printed requires a separate screen.

NEW TECHNOLOGY

Digital has made significant effects in the wide printing of textiles in furniture and sportswear, replacing the slow silk screen

equipment. It is obvious that the ability to change the design at a moment when there is no long switching time or high cost

rotation of the screen printing unit. However, not all digital printing systems are compatible with the stringent requirements

for high impact resistance and safety standards for “apparel” products.

|

|

| Blue Fashion Cartoon Custom Webbing For Metal Hook | PO-16014 20mm Patterned Polyester Webbing |

For all owners, printing branded ribbons will help you decorate your packaging. When you want to pack the gift card in the

pillow box, the printed ribbon will be subjected to a special presentation. In order to pack gift baskets and bundled products,

the possibilities are endless.

The Hybrid Press

Hybrid press printings are emerging on the market, and have produced a lot of enthusiasm. A hybrid press is a combination

that allows for seamless switching between digital and conventional printing methods. This has a lot of advantages for both

operators and customers. For the customer, these hybrid printers offer high quality, cost-effective results.

|

|

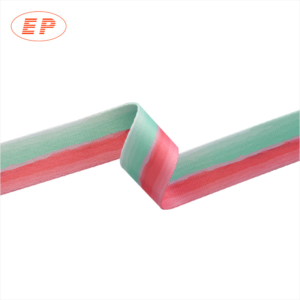

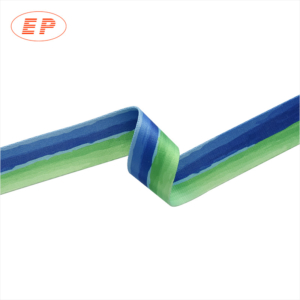

| PO-16011 Custom Polyester Printed Webbing | PO-16010 Printing Polyester Binding Tape |

Which webbing Printing Machine Is Best?

The best part is the economy! Custom ribbons can print less than one dollar a yard and sell it to customers in a few dollars per

lot. When you consider the value of advertising and the ability to print with custom ribbons, the machine does not take a long

time.

Determine which method to choose to print clothing labels is determined by the individual. Deciding which machines and

methods are the best will depend on the material of the label, and what kind of final result. Another consideration is longevity.

The longer you want your clothing label to last, the longer it will take for the printing method, and in this area, traditional

printing still occupies a supreme position.