Ropes are closely related to our daily life due to its various functions and convenience. For examples: Heavy loads, such as hay and straw are secured with ropes; rope is also used in rural recreation for water skiing and mountain climbing. It is also used to tie camping gear on pack mules, horses, and vehicles. However, ropes are not versatile because different ropes varies in its materials, size, and different uses require different kinds, sizes and lengths of rope. So, how can we select the ideal ropes to match up our purpose?

ideal ropes

Factors considered to select the ideal ropes:

- Construction

Rope is made from a variety of materials, each of which has different characteristics. So, its construction varies depending on the materials. Natural fiber ropes are usually woven while synthetic ropes are often braided.

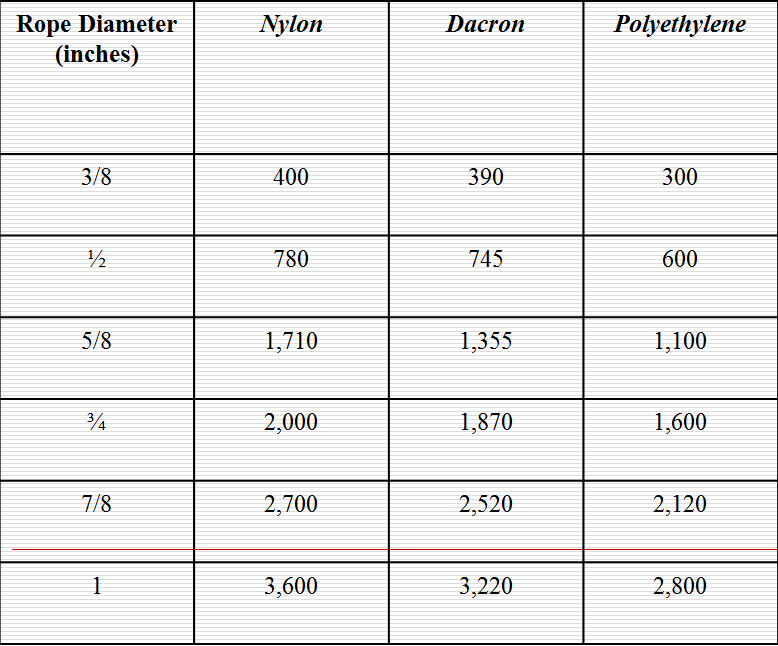

- Strength:

Rope strength is measured as a breaking load. The breaking load is the amount of weight a rope can hold without being pulled apart. And the strength depends on the diameter and the material of which it is made. Usually, common diameters of rope are ¼”, 5/16” , 3/8”, ½”, 5/8”, ¾”, 7/8”, and 1”(inches).

- Durability & Flexibility

The durability of a rope depends on its ability to resist deterioration when exposed to chemicals, sunlight, water and wear. Flexibility determines how easy it is to handle or process the rope.

ropes parameters (inches)

EP® is a professional manufacturer of nylon ropes, polyester ropes, cotton ropes, etc. Next, let’s take a look at the ropes of different materials.

Cotton Rope is the most common natural fiber rope. Although it is not as strong as manila and sisal, cotton rope is more desirable in the livestock handling due to its softer surface texture. Cotton rope is also susceptible to rot and decay and has a tendency to swell when it gets wet, which decreases its workability.

Nylon ropes are the strongest synthetic ropes available. They are soft, pliable, and less susceptible to rot and mildew than natural fiber ropes. Although these ropes do stretch when wet, they retain their strength under wet conditions. Excessive heat will melt nylon ropes and long exposure to sunlight will cause the fibers to become brittle and decay.

ideal ropes

Polypropylene and polyethylene ropes are rougher in texture and less flexible than nylon ropes. “Poly” ropes are also susceptible to heat and sunlight. It is easy to obtain and cheaper. So it is widely used. Polyethylene rope also floats in the water, making it suitable for boat and dock work.

About EP®

As a manufacturer specializing in webbing and ropes, Dongguan EP® Launcher International Co., Ltd was established in 2010. We are fully experienced in manufacturing a variety of webbing and ideal ropes such as nylon webbing, Polyester ropes, etc. And we enjoys high reputation in this industry of China!